Greenlane Products

Accelerating the Energy Transition

Greenlane's products remove impurities in biogas to create clean, pipeline-quality, low-carbon and carbon-negative Renewable Natural Gas, also referred to as biomethane. Greenlane is the only gas upgrading company to offer multiple core technologies: water wash, pressure swing adsorption (PSA), membrane separation, plus proprietary biogas desulfurization.

Greenlane engineers its products to solve the industry's toughest challenges, delivering high performance at low cost built around standard product platforms. Once operational, Greenlane provides aftercare service, including 24/7 technical support and remote monitoring, as well as maintenance and spare parts.

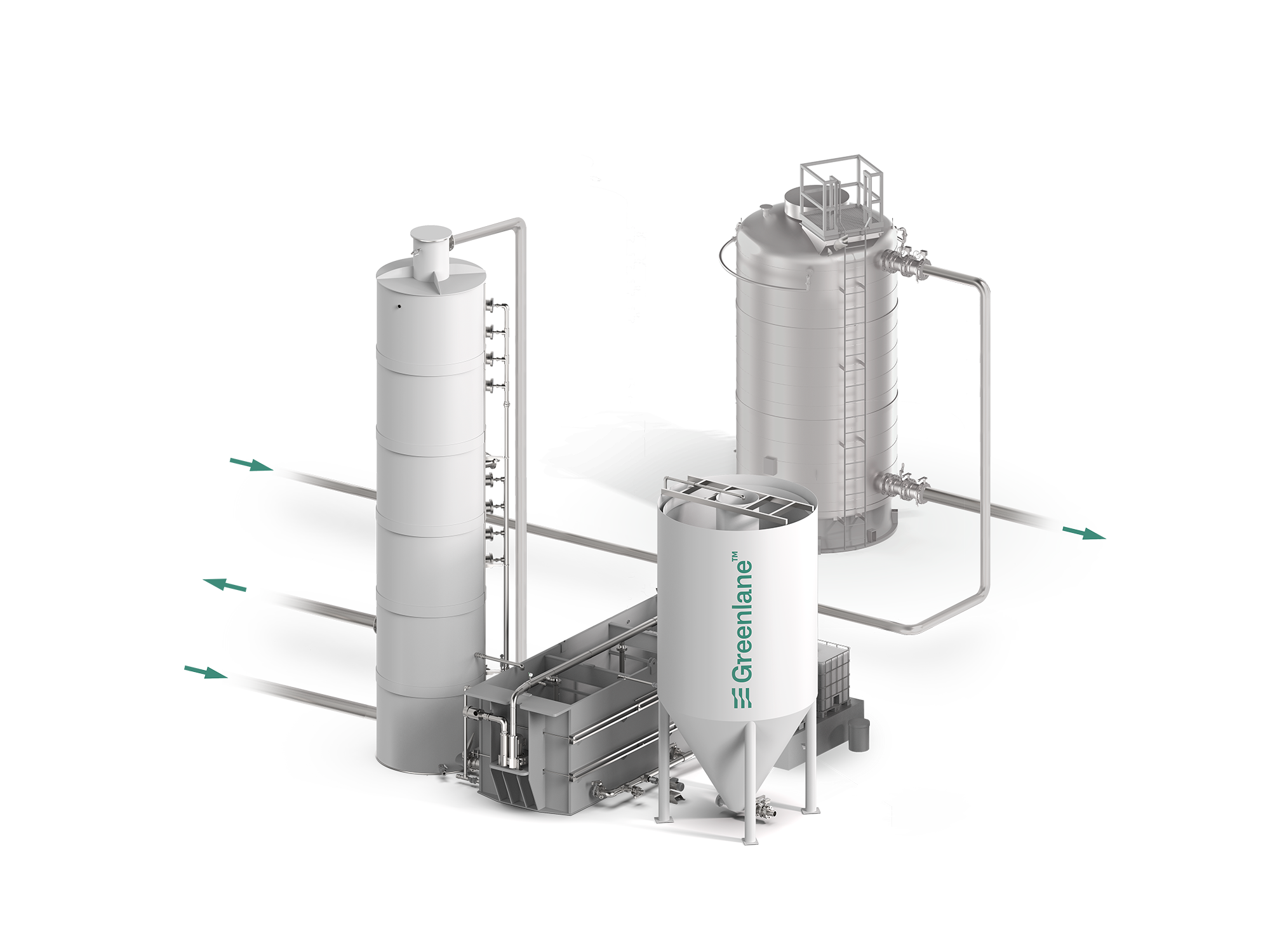

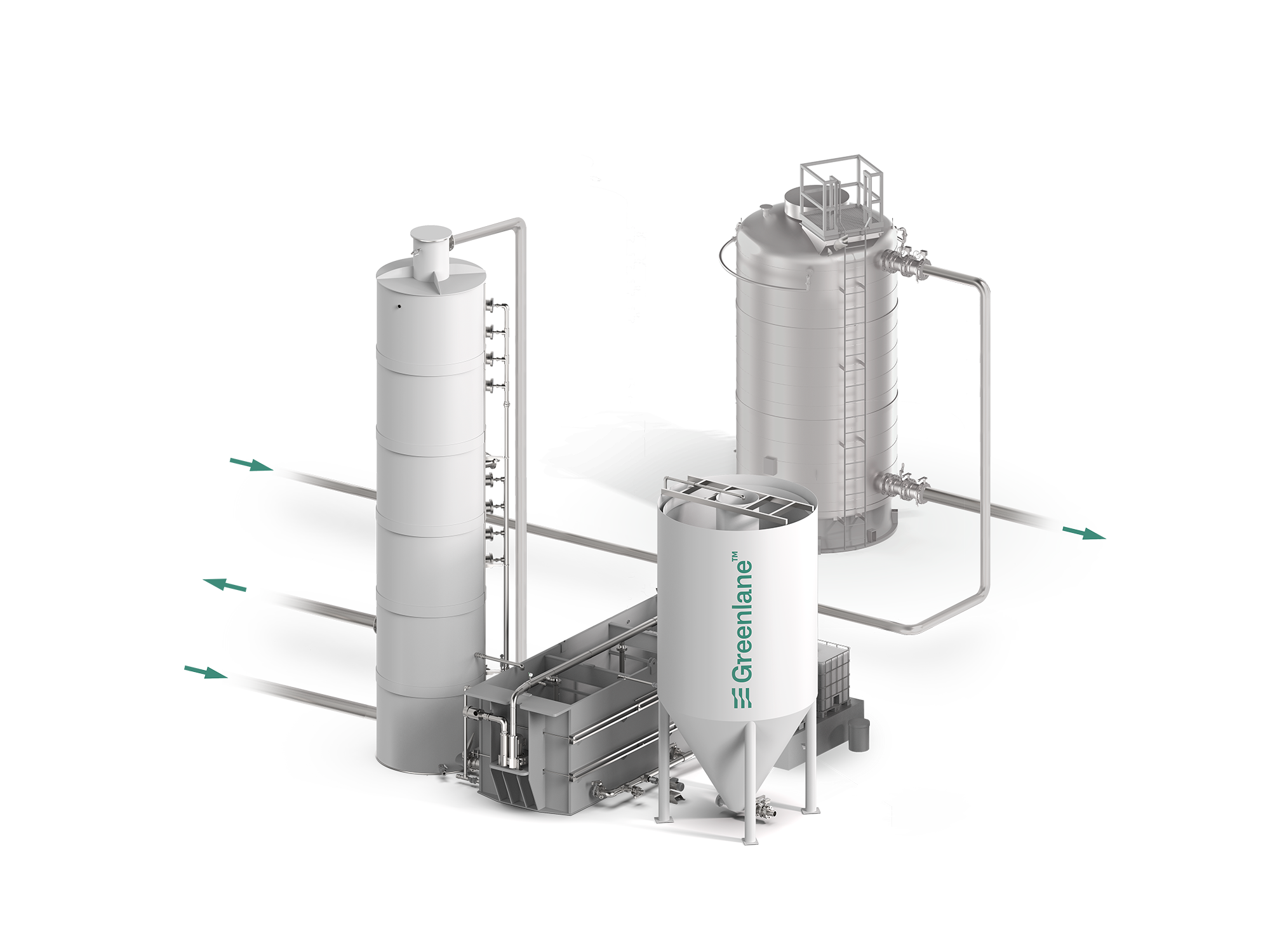

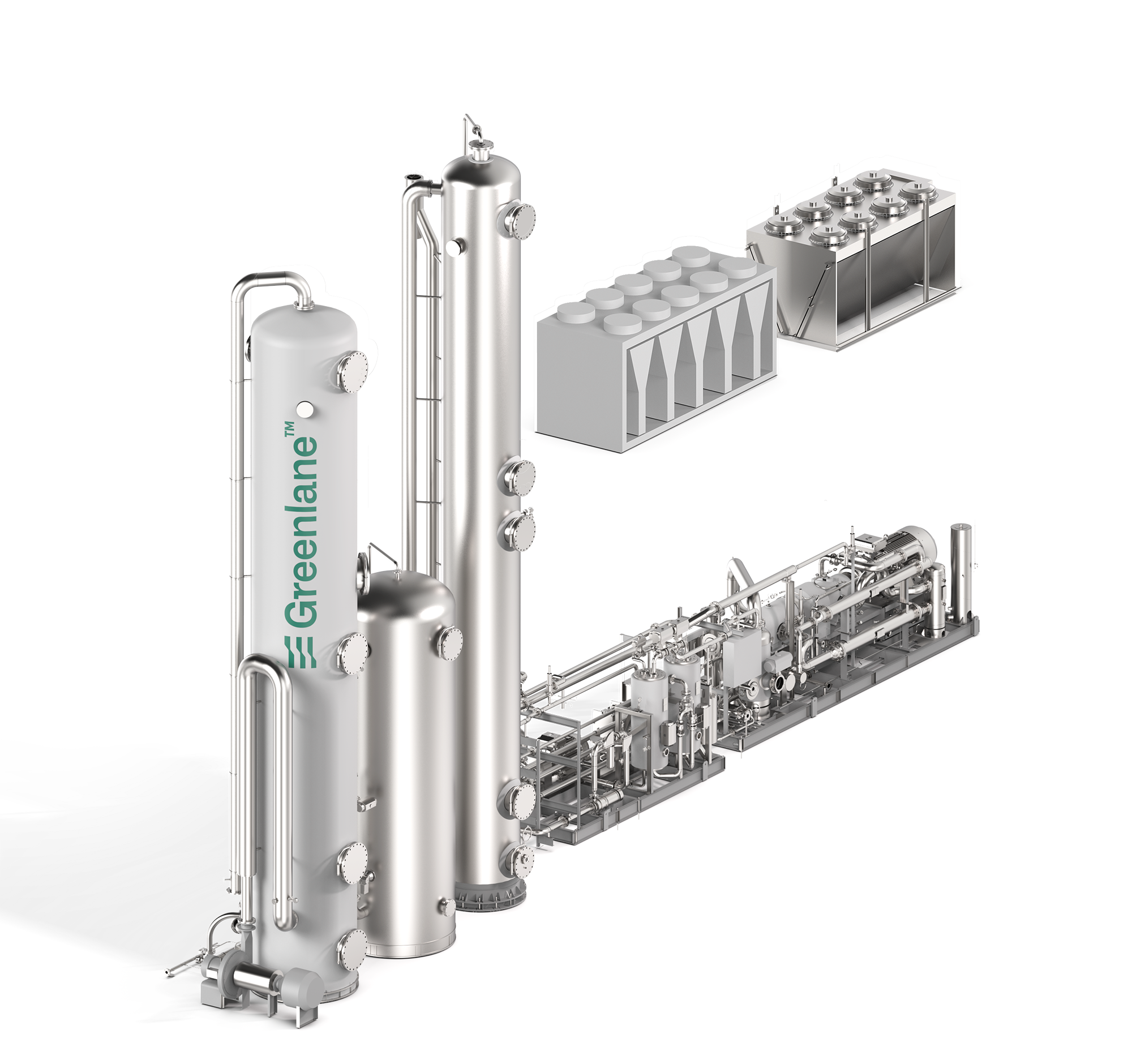

Cascade H2S

Regenerative removal of H2S from biogas

Every biogas project requires hydrogen sulfide (H2S) removal. The Greenlane™ Cascade H2S product line delivers an established and robust regenerative biogas desulfurization solution where the goal is high performance at low cost.

The raw untreated biogas feeds into the bottom of a scrubbing tower where it flows, countercurrent, to a proprietary liquid chemical solution. Treated gas exits through the top of the scrubber. The sulfur-rich liquid solution is regenerated in a separate oxidation tank after which it is transferred to a sedimentation tank to allow the elemental sulfur solids to drop out. Clean, regenerated solution returns to the scrubbing tower in a continuous and efficient process.

Greenlane™ Cascade H2S neither requires the addition of oxygen nor adds it in the process. This is critical because oxygen is difficult and costly to remove after being added directly into the digester or to the biogas stream for biotrickling or activated carbon filters in alternative approaches to H2S removal. Excess oxygen can lead to pipeline shut out due to non-compliance with injection specifications. Greenlane™ Cascade H2S is easy to install and operate, creates sulfur-rich effluent that can be spread on fields as fertilizer, and eliminates many of the operational issues and costs that come with traditional biological scrubbing and media-based H2S removal systems.

Product Details

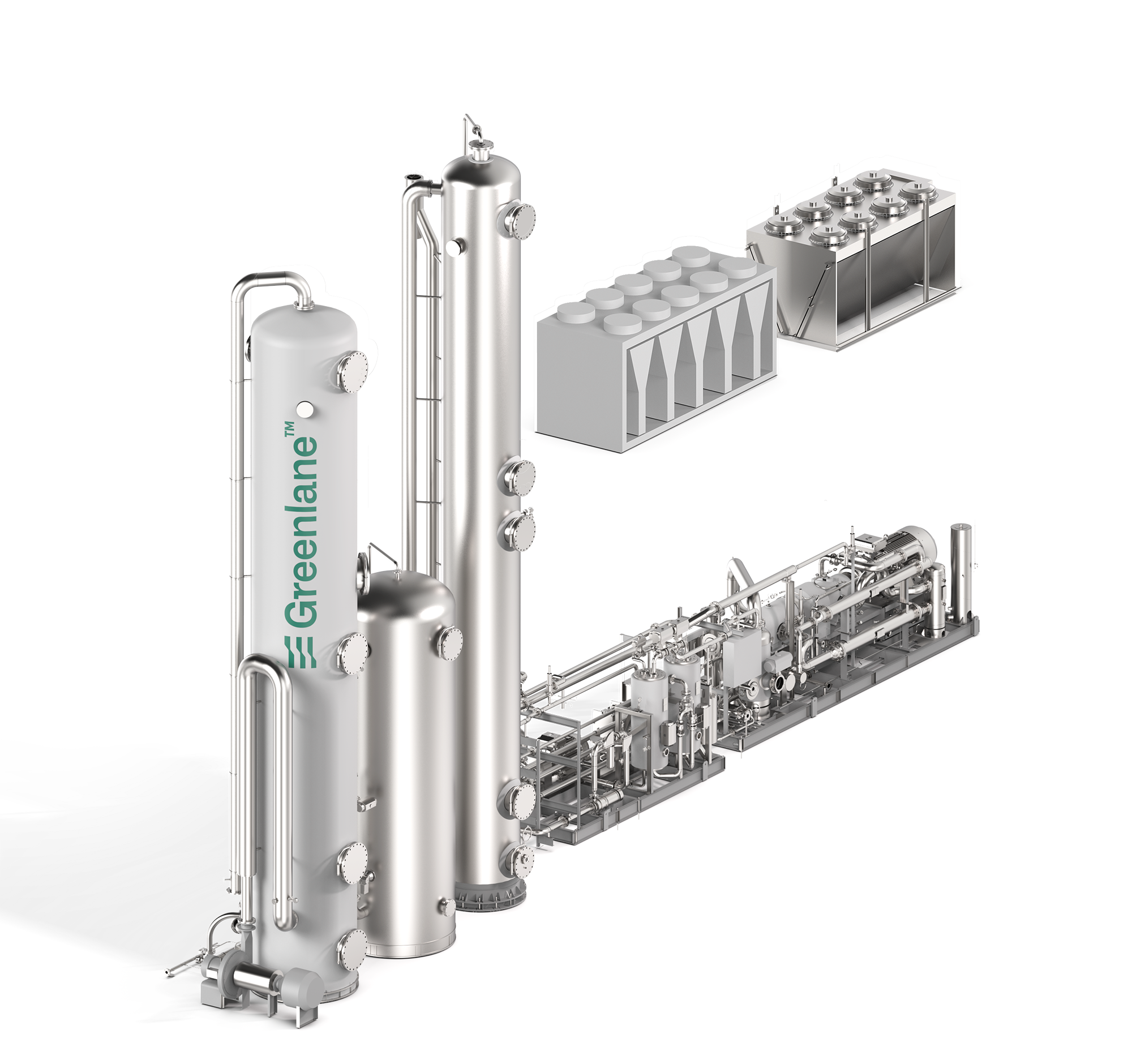

Cascade MS

Gas Upgrading with Membrane Separation

Greenlane™ Cascade MS uses multi-stage, high-efficiency tubular porous membranes to separate the carbon dioxide from the biomethane in a process called permeation. As the biogas passes through the tubes, the smaller carbon dioxide molecules pass through the walls of the highly selective permeable membranes, while the larger biomethane molecules do not.

Our systems offer reliable performance and high biomethane recovery, which is typically over 99%.

Product Details

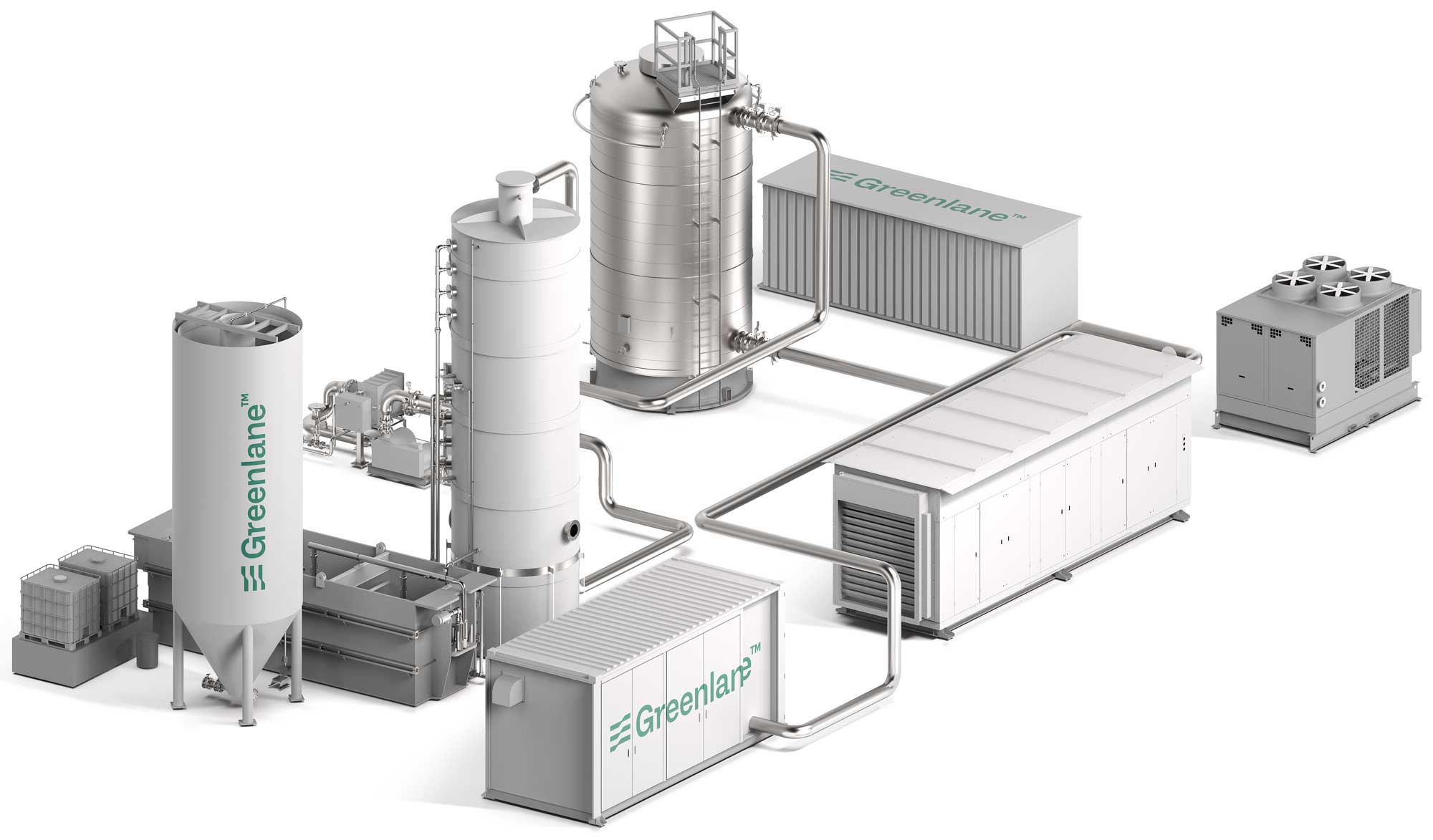

Cascade H2O

Gas Upgrading with Water-Wash Technology

Greenlane leads the field in water-wash (or water-scrubbing) technology, the most deployed biogas upgrading technology in the world. Greenlane™ Cascade H2O uses counter-flow water to scrub away impurities from the inlet gas stream without the need for chemicals or heat.

Greenlane™ Cascade H2O utilizes a simple and robust process. Raw untreated gas from biodigesters or landfills is compressed then flows upwards through a cascade of water. The carbon dioxide, hydrogen sulfide, volatile organic compounds, and siloxanes dissolve into the water, while the biomethane does not. The biomethane is then dehydrated, providing pure, dry RNG. The water is cleaned of the impurities by counter-flowing air through it and reused in a closed loop.

The Greenlane™ Cascade H2O product line comprises five models designed to meet a wide range of flow-rate requirements. All the models are of a standard modular design with a compact footprint. Where larger capacity is required, we provide multiple systems in parallel.

Product Details