Today's state-of-the-art landfill gas upgrading technology is too costly for the performance it delivers. The challenge is achieving low cost and high performance at the same time when O₂ and N₂ need to be removed.

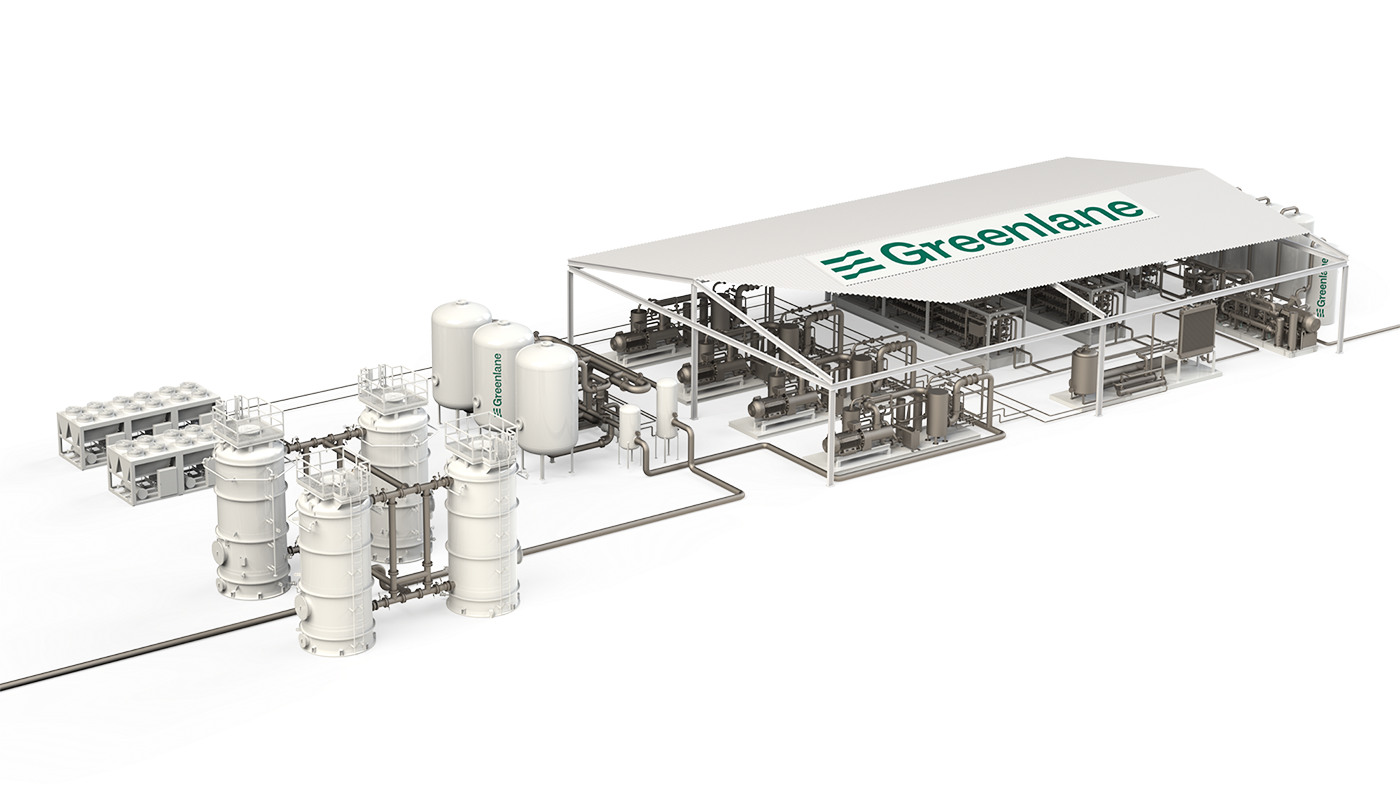

Greenlane is addressing this problem with our next-generation Cascade LF landfill gas upgrading system, designed to achieve maximum methane recovery with minimum capital expenditure. It features:

- proven, reliable, and established technology elements integrated in a patent-pending process, and

- a modular system design that is configurable and adapts to rapidly changing inlet gas flow and composition.

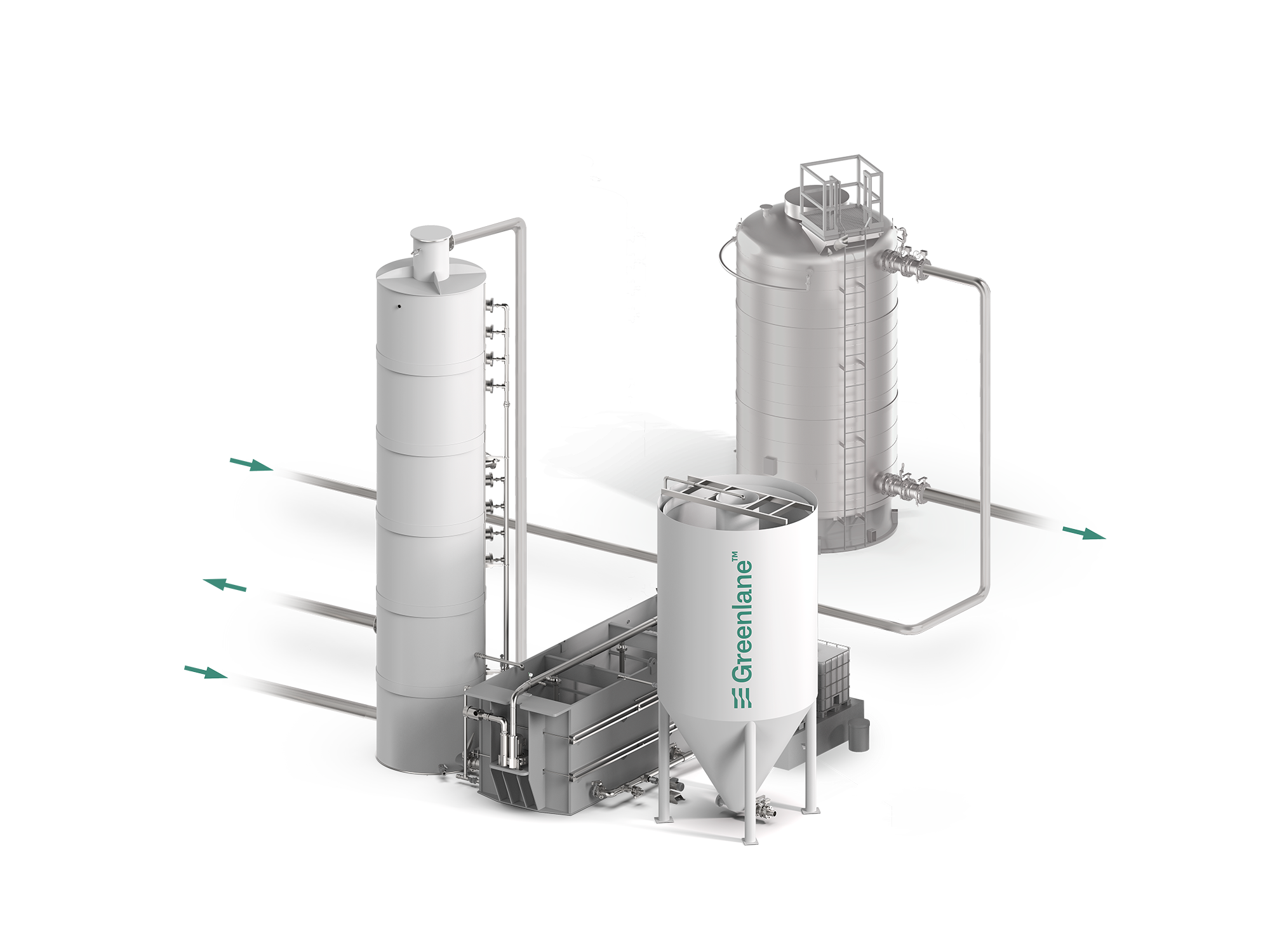

The first process step is pre-treatment. Raw landfill gas passes through activated carbon, removing Hydrogen Sulfide (H₂S). For higher H₂S and flow applications, optional Cascade H₂S (regenerative bulk H₂S removal) is available for lower OPEX. Subsequent pre-treatment removes VOCs and Siloxanes using formulated activated carbon. For high levels of contaminants, a proprietary regenerative temperature swing adsorption (TSA) module is used.

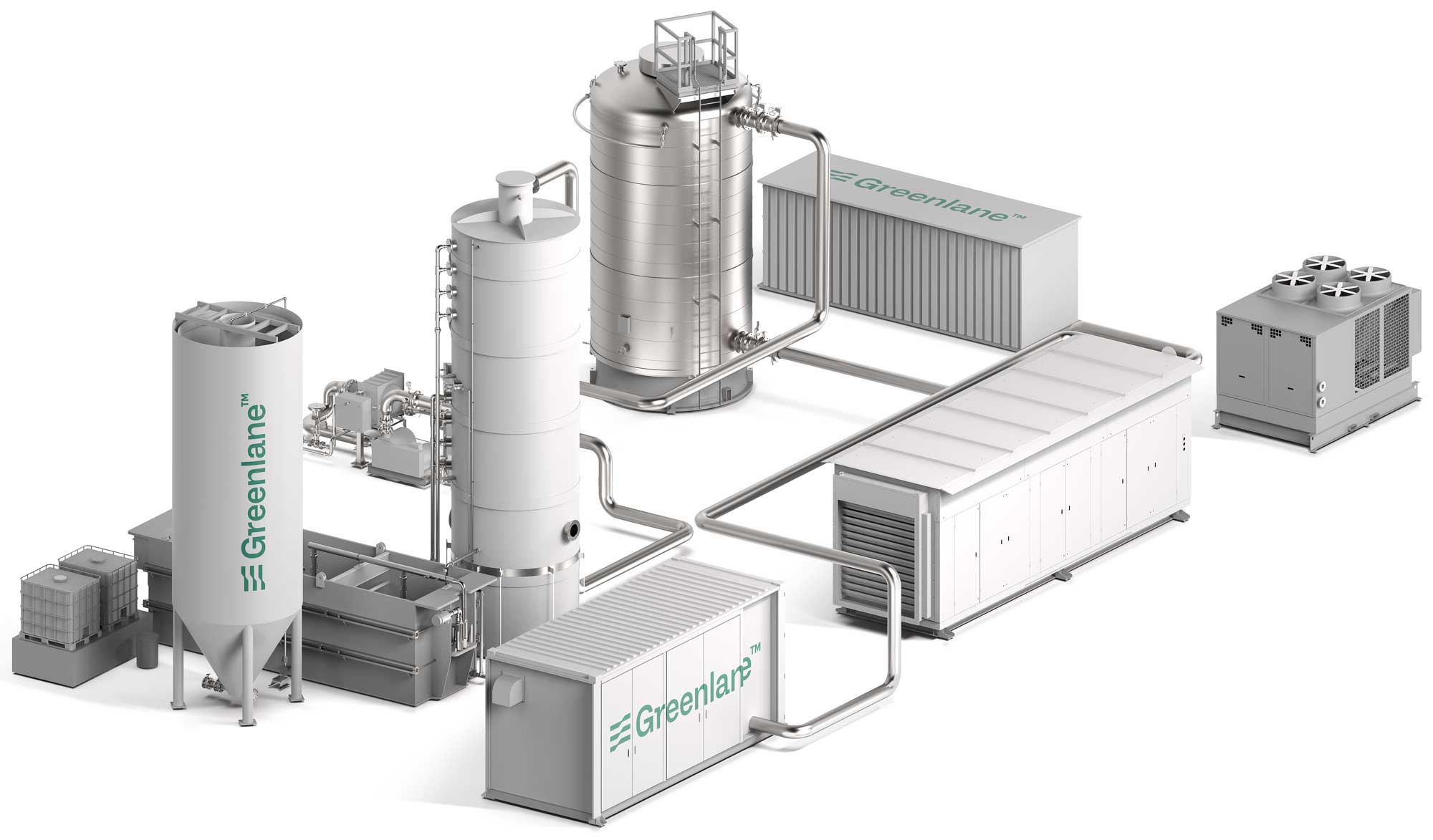

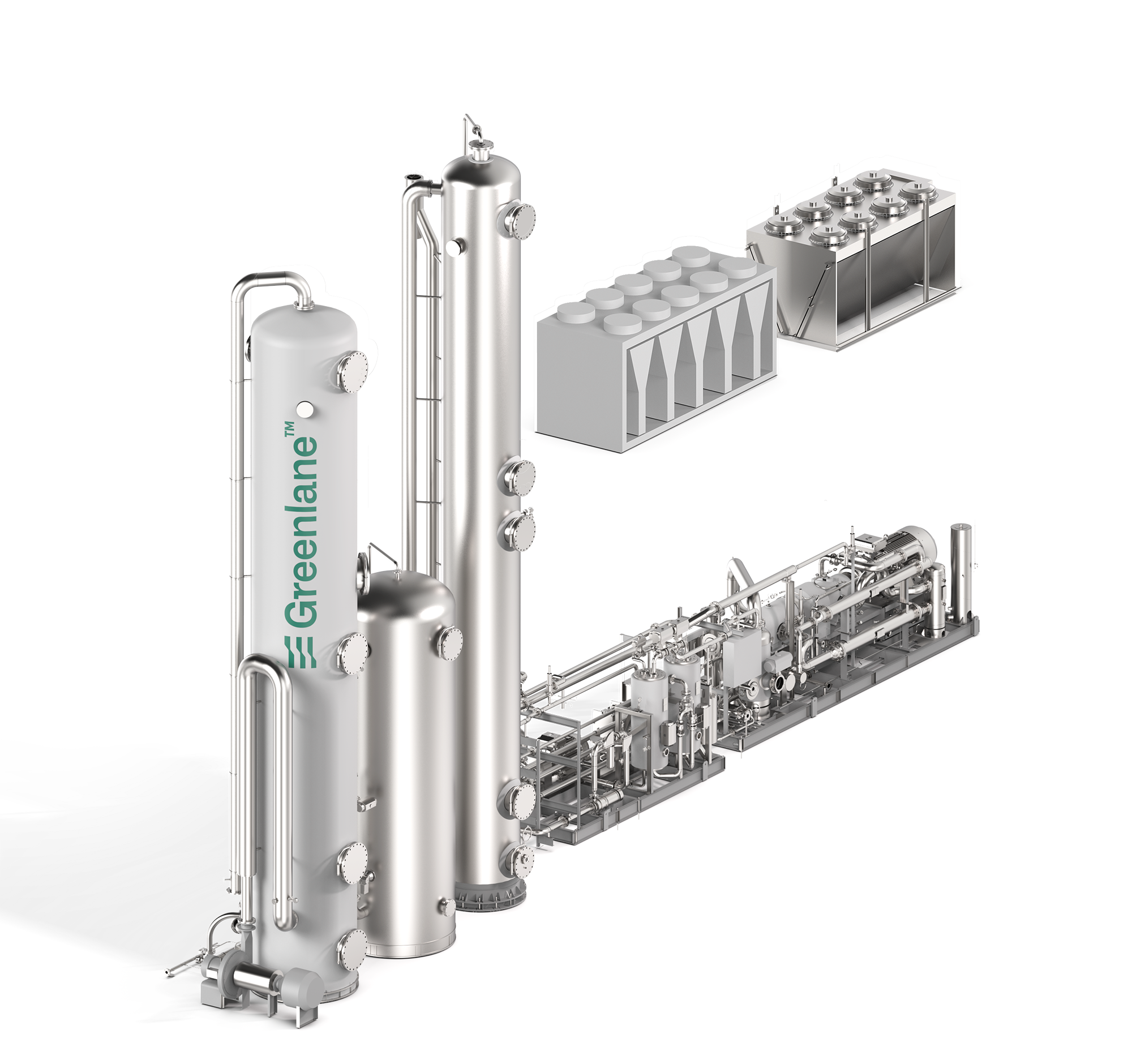

Pre-treated gas is then compressed, dewatered, and temperature-controlled. A patent-pending integrated upgrading process using membrane separation featuring permeate sweep technology and catalytic deoxygenation effectively eliminates CO₂ and O₂ with no need for a dedicated dryer. Elimination of CO₂, O₂, and H₂O creates the conditions for optimal subsequent N₂ removal. The separated CO₂ stream can be sequestered or used for other value-added purposes. At lower O₂ levels, catalytic deoxygenation is not required.

In the final upgrading step, only enough N₂ is removed using a proprietary equilibrium pressure swing adsorption (PSA) module to meet the final biomethane/RNG product specification.

With 24/7 expert support, remote monitoring, and flexible service options, Greenlane’s Cascade LF delivers high performance and reliability for landfill gas projects, backed by decades of industry experience.

Product Details